Omni-directional Chocks

Category:

Anchor Series

Keyword:

Omni-directional Chocks

Still deciding? Get samples first, Contact US !

Description

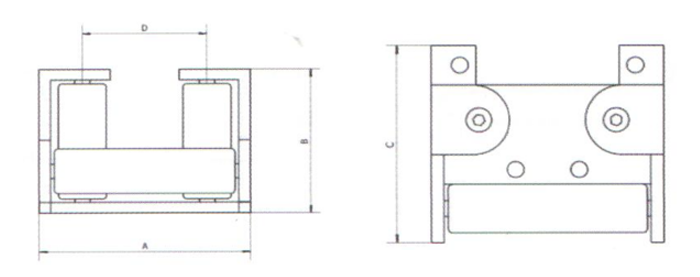

Product Dimension

| Part | A(mm) | B(mm) | C(mm) | D(mm) |

| AN-AR220 | 110 | 60 | 80 | 58 |

| AN-AR221 | 150 | 80 | 100 | 105 |

| AN-AR222 | 220 | 90 | 120 | 175 |

A marine universal cable guide is a device used on ships to guide and control the course of a cable so that the ship can be safely and efficiently attached to a dock or other vessel while berthing, mooring or towing.

Structural components

Base: Used for fixing on the deck or side wall of the ship, usually installed by welding or bolting. The structural strength and stability of the base is critical to the performance of the entire cable guide.

Swivel head: mounted on the base and able to rotate freely around a vertical axis. The swivel head usually has bearings or rollers inside to minimize friction during rotation.

Pulleys or Rollers: Mounted on the swivel head to guide the direction of the cable. The number and arrangement of pulleys or rollers can be designed according to different needs, and there are common forms such as single pulley, double pulleys, multiple pulleys or rollers.

Guide sheave: Some universal cable guides may also be equipped with a guide sheave, which is used to further guide the direction of the cable to ensure that the cable can maintain the correct direction when passing through the cable guide.

Other accessories: According to the specific design and use requirements, the marine universal cable guide may also include some other accessories, such as limiters, stops, protective covers, etc., to improve the safety and reliability of the cable guide.

Production Strength

In terms of technology, Jiuchang Metal's factory is equipped with advanced equipment, such as casting and polishing production lines and CNC machining centers, and is supported by a digital process management system to ensure processing efficiency and accuracy. In surface treatment, it is proficient in a variety of processes and can customize different gloss and texture effects to enhance the added value and competitiveness of products. Meanwhile, the company always adheres to the quality bottom line, follows the ISO quality management system, and conducts comprehensive and multi-link inspections. It has obtained multiple certifications to ensure the stable and reliable delivery of products.

Quality Control

Adhering to the philosophy of "technology-oriented and customer-first," Jiuchang Metal provides customers with full-process services from design to production. With its efficient production capacity, cost advantage, and perfect after-sales service, it has established long-term cooperation with many enterprises and become a preferred regional metal processing supplier. In the future, the company will promote technological innovation and equipment upgrades, adhere to the concept of green manufacturing, and build an intelligent and environmentally friendly demonstration factory to provide better products and services for global customers and jointly create a new chapter of development with industry partners.

Our Services

Since its establishment in Dongying, Shandong in 2017. Dongying Jiuchang Metal Products Co., Ltd. has been committed to the casting, processing, and surface treatment technical services of metal products. Leveraging the local industrial resources and mature industrial chain, it has provided high-quality metal processing and polishing solutions for various industries. With a wide range of main businesses, it can offer full-process services from casting to surface polishing for industries such as mechanical manufacturing, medical devices, automotive parts, yacht hardware, and architectural glass hardware. It covers a variety of materials and processes to meet different customer needs.

Related Products

Omni-directional Chocks

Category:

Anchor Series

Keyword:

Omni-directional Chocks

Still deciding? Get samples first, Contact US !